Roofing Flashing Bending Machine

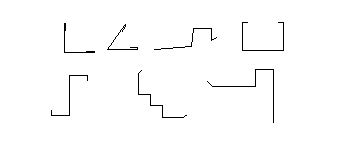

■ Roof Flashing Profiles Brief Introduction

Roof flashing finishes off hips and ridges. A ridge capping provides an effective watertight barrier, as well as an aesthetic finish to the cut ends of the sheet at the ridge and hip lines. Roof flashing system can provide the utmost protection in roofing with its industry-leading design to decorate as well as optimize the function of the roof and increase the life span of the roof. Our many different metal material options provide you with a wide array of design options to consist with your shingle style. Roof flashing made of fiberglass provide a watertight, and easy to install and are long-lasting solutions for utility buildings.

■ Roofing Flashing Profile Folding Machine Technology Specification

The system adopts hydraulic drive mode, up and down clamp to achieve the clamping steel plate; unique parallelogram hinge mechanisms to achieve the flap rotation to bending plate, This is the bending machine special for production of roofing cap, gutter, etc. with its cheaper price, it is popular in the world market.

■ Main parameters- Roofing Flashing Profile Folding Machine

|

ITEM

|

CONTENT

|

|

Max bending thickness

|

1.0 mm

|

|

Max bending length

|

6000 mm (Optional)

|

|

Min. folding sizes

|

10 mm

|

|

Hydraulic station power:

|

3kw

|

|

Machine Size:

|

6500mm x 800mm x 1800mm

|

|

Weight:

|

about 1500kg

|

■ Roofing Flashing Profile Folding Machine Application

This machine can be used for production the steel construction profiles, such as the roof cap, flashing, door and windows frames, edging and a variety of income side, the corners components. Also be used for other sectors of the sheet metal bending, Flashings for metal roof and wall cladding.

TAG: Roofing Flashing Profile Folding Machine, bending machine

Last:Ridge Tile Cap Machine

Next:NC Folding and Slitting Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,