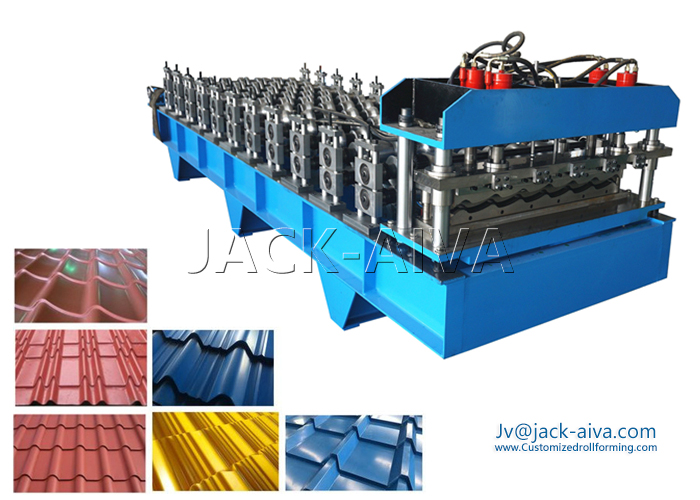

Roof Tile Machine

■ Roll Forming machine for the manufacture of the metal roofing step tile

We offer custom style Metal roofing step tile machines, our roll forming machine has the ability to produce conventional custom length products and multiple step standard lengths allows tile manufactures a wide range of production capabilities.Steel Roofing tile roll forming machine design allows for the production of traditional modular roof tile sheets and fastened tile panels. The tile roll forming machine design allows for the production of traditional tile panels and fastened tile panels. This machine can produce through fastened panels in steel, creating a perfect, scrape-free finish. The colored steel tiles produced by this line look beautiful, elegant and noble. They are widely used as the roof of garden-like factory, hotel, exhibition center, villa, civil construction, etc.

■ Machine Components- Steel Roof Tile Roll Forming Machine

This Steel structure roof tile roll forming Machine is including Roll-forming tools, unwinding, cutting and final packing. All of this equipment is manufactured to order according to the client requirements and concepts. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface. The normal technology for our steel roof step tile roll forming machines is as following,

De-coiling - Coil sheet guiding & feeding - Roll forming - cut to length - stacking production

The present roll forming machine only can produce one profile.

■ Main Parameters - Automatic Steel roof Tile machine

|

Main motor power::

|

5.5kw

|

|

hydraulic station power:

|

5.5kw

|

|

Hydraulic pressure:

|

10-12Mpa

|

|

ROLLER STATIONS:

|

15 ~ 24 sets

|

|

MAX Forming Speed:

|

15m/min, can be supplied according to client request

|

|

Control System :

|

Fully Automatic Control System with PLC, Easy operation: Key in the length and quantity on the control panel

|

|

Capacity Length:

|

up to 9999 mm (optional)

|

|

Material of Sheet:

|

Soft Quality (Annealed) Galvanized Sheet

|

|

Sheet Thickness:

|

0.4 to 0.7mm

|

|

Nodal distance:

|

adjustable according to requirement (>=250mm)

|

|

Total Gross Weight:

|

About 7500kgs

|

|

Line size (Lx w x h) mm

|

12000×1500×1100

|

■ Metal Roof Tile Sheets Applications

The Roofing tile sheets with step press can increase the intensity too much, and obtain the lower weight ratio, with the advantage, this trapezoidal sheet products are widely adopted by commercial and industrial applications, for factories, shop lots and apartments, etc. The available materials for this tile sheet are including colored steel, GI steel coil, aluminum, or the other metal suitable for cold forming technology.

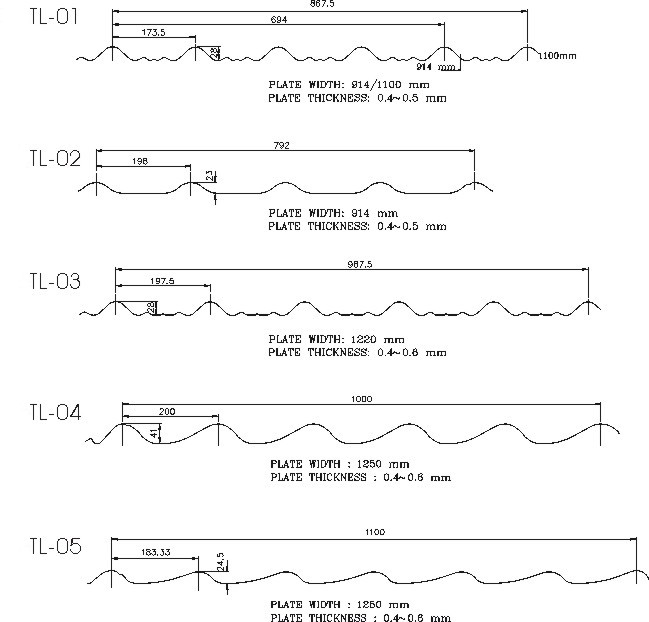

we can manufacture as per customer provided drawings or real objects of sectional materials. The following is some profiles as reference.

■ Related steel roof tile profiles as reference

Custom profiles are welcome! For information on metal roof tile sheets profiles by our roll-forming mills, please contact with us!

TAG: Roofing Tile Roll Forming Machine, Roofing tile machine, Tile sheet machine, Tile machine, Tile-roof panel

Related steel roof tile profiles as reference

Last:Wall Panel Roll Forming Machine

Next:3D Roof Tile Roll forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,