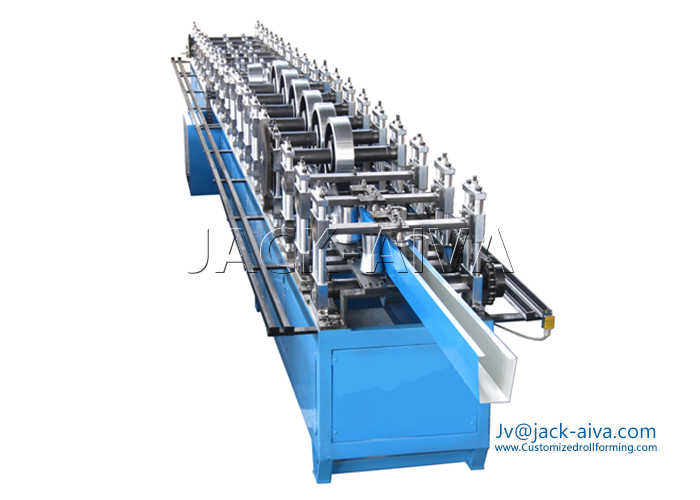

Roof Flashing Roll Forming Machine

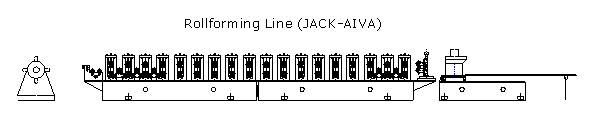

■ Roll Forming machine for Production of Roof Flashing Profiles

Roof flashing finishes off hips and ridges. A ridge capping provides an effective watertight barrier, as well as an aesthetic finish to the cut ends of the sheet at the ridge and hip lines. Roof flashing system can provide the utmost protection in roofing with its industry-leading design to decorate as well as optimize the function of the roof and increase the life span of the roof. Our many different metal material options provide you with a wide array of design options to consist with your shingle style. Roof flashing made of fiberglass provide a watertight, and easy to install and are long-lasting solutions for utility buildings.

Our roll forming machines can be designed according to client’s sample or profile drawings, various roof flashing profiles can be obtained by our machines, can be used to construct the buildings together with the step-tile roof panels.

■ Roof Flashing Roll Forming Machine Components

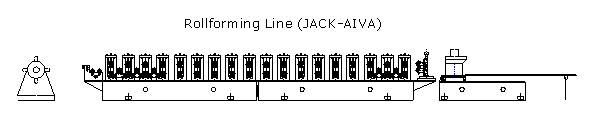

Roof Flashing Roll Forming is consisted of de-coiler, material feeding device, roll forming machine, straightening device, tracing cutter with round saw, run-out table, etc.

■ Roof Flashing forming machine parameters specification

|

Item

|

Content

|

|

Raw material thickness:

|

0.4-0.6mm

|

|

Line speed:

|

3-5m/min

|

|

Rollers station

|

12 sets

|

|

Main power:

|

4kw

|

|

Hydraulic station power:

|

4kw

|

|

Hydraulic pressure:

|

16Mpa

|

|

Control system:

|

PLC Control (Panasonic brand); Code (Omron brand)

|

|

Tolerance of length:

|

10m+/-2mm

|

|

Material of Sheet:

|

Soft Quality (Annealed) Galvanized Sheet

|

|

Total Gross Weight:

|

About 3500kgs

|

|

Line size (Lx w x h)

|

7500 mm×1000 mm×1100 mm

|

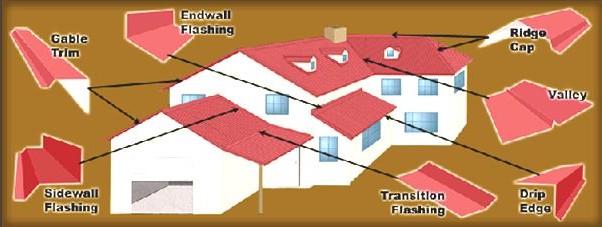

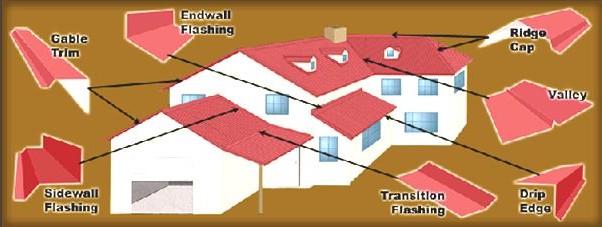

■ Roof Flashings Applications

Rain penetration through tile roofs is often caused by the cracking of sand and cement adhesive frequently used for tiles. Sand and cement adhesive has little flexibility and can crack due to natural movements in a house or temperature fluctuations. Metal tile cap has been purposely developed to overcome the disadvantages of the traditional sand and cement adhesive. Tile ridge cap pointing material was tested to cyclic fatigue loading conditions as per AS2050. The sample system adhesive successfully passed the test criteria at the design pressure.

We can manufacture as per customer provided drawings or real objects of sectional materials, customization is welcome.

■ Flashings for metal roof and wall cladding

The flashing products can be satisfactory for use as roofing panel abutment, flashings on tiled roofs, or slated roofs.

So the end-wall flashing, gable trim, ridge cap, roll formed valley gutter, roof battens, drip edge and sidewall flashing have been developed.

TAG: Roof Flashing Roll Forming Machine, Rain Gutter machine, Roof Ridge Tile Cap Roll forming machine,

Last:Roof Cap Machine

Next:Ridge Tile Cap Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,