Cable Tray Roll Forming Machine

■ Cable Tray Roll forming machine for production Brief Introduction

The cable tray or cable ladder production in the present market, with roll forming advantages, cable tray sections have a much wider scope of cross section if compared with press braked sections and without length limitation. Roll Forming Production speed is much faster than with press brakes, particularly production complex profiles without secondary operations.

With full experience in this roll forming industry, our Cable tray roll forming machine adopts cantilever style roll former technology, so that the different width cable ladders can be manufactured by one line after adjustment, and replace the punching moulds.

We are the professional ladder type cable tray roll forming machine, our line could be run for cable tray and cover cable tray production, the line can be custom prepared according to client requirements.

■ Cable Tray Roll Forming Machine Technology Specification

The lines we propose allow industrializing any type of cable tray. Our roll forming lines are suitable to manufacture cable trays, in different widths and heights, by just changing the coil and roll formed width.

The whole line is electronically controlled, in order to ensure the right feeding, punching and cutting is achieved.

The production line components is depended on client individual request, the normal technology flow is as following,

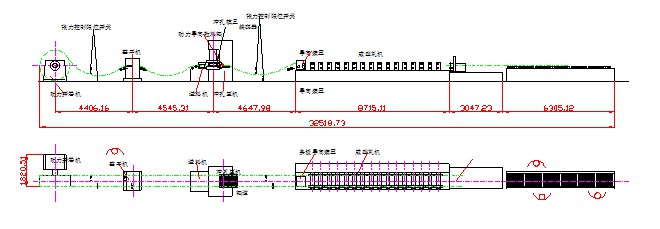

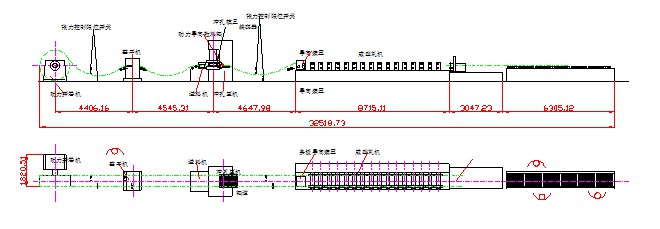

Auto-de-coiler-----leveling----servo feeding----hole punching----cutting-----conveying----roll forming----collection table

■ Main Parameter- Cable Tray Roll Forming Machine

|

Line structure

|

Portal-type frame style, A3 steel

|

|

Forming Roller Stations:

|

16 Stations

|

|

Forming Roller shaft:

|

Φ80mm

|

|

Forming rollers

|

Cr12Mov, Quenching, hardness HRC58-60º

|

|

Forming Speed:

|

0 -6 meters / min

|

|

Main motor:

|

11kw,

|

|

Material of Sheet:

|

Soft Quality (Annealed) Galvanized Sheet

|

|

Sheet Thickness:

|

0.5mm-1.5mm

|

|

Steel plate width

|

200-600mm

|

|

Cutter Device

|

Hydraulic press or saw style is optional

|

|

Main machine dimension

|

13000*1500*1200m

|

|

Control mode

|

PLC Control

|

■ Cable tray profiles Application

A cable tray system, is "a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways. Cable trays are used to hold up and distribute cables.

Cable tray roll forming machine is special designed for its production.

For more detail about the cable tray system, please do not hesitate to contact with us directly.

TAG: Cable tray, cable tray roll forming machine, roll forming machine, cable ladder roll forming machine, Cable Tray Production Line, cable tray roll forming line, Cable tray making machine, Slotted Cable Tray,

Last:Electrical Cabinet Case Production line

Next:Scaffolding pedal Roll Forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,