Electrical Cabinet Case Production line

■ Roll forming machine for production Electrical Cabinet Frame or Electrical Cabinet Box

With roll forming technology advantages, The Electrical cabinets frame or box sections by our roll forming line are widely adopted in the following fields, the electrical cabinet sections of paper machinery industry and machine tools industry, AC&DC control cabinet and electrical cabinet sections of spinning and chemical fiber machinery industry, mining and building machinery industry, also high or medium-voltage electrical transmission control cabinet sections of telecommunications industry. The scope of cross section if compared with press braked sections is without length limitation. more efficient, and without secondary operations. From simple profile to complex profiles, we can manufacture custom electrical cabinet roll forming machine.

■ Technology specification- Electrical Cabinet Roll forming machine

The whole Roll forming line components is depended on client individual request. The possible auxiliary equipments are included de-coiler, straightening device, pre-and post-punching, stationary cut-off machines, run-out table, etc. The around working situation is as following, the coil is manually Loaded to the discharging rack (UNCOILER), and manually tightened. After the coiling material is leveled by the leveling machine, the feeding roller is driven by the servo motor to feed the length, and the punching is completed through two sets of punching die and punching die. And the required cutting angle of the splicing, and then enter the forming machine through the guide plate, through the 18 sets of cold-bending forming rolls to complete the common plate flange forming, after the flange forming, through two sets of punching die and a set of cutting die, that is completed The forming of one of the four sides of the valve body is cut off, and the cut work piece can be folded into a frame by hand, and the fastening component is firmly connected to form a complete valve body.

■ Main parameter - Electrical Cabinet Roll Forming Machine

|

Line structure

|

Portal-type frame style, A3 steel

|

|

Raw material

|

Soft Quality (Annealed) Galvanized Sheet

|

|

Thickness:

|

1.0-1.6mm

|

|

Line speed:

|

1-15m/min (adjustable)

|

|

Forming Roller Stations:

|

25 Stations

|

|

Forming Roller shaft:

|

Φ60mm

|

|

Forming rollers

|

Cr12Mov, Quenching, hardness HRC58-60º

|

|

Length tolerance:

|

±0.3mm/1000mm

|

|

Punching hole distance tolerance

|

±0.3mm/1000mm

|

|

Min frame sizes

|

120*120mm

|

|

Processing method:

|

cut To length / single straight piece / 口 type

|

|

Efficiency:

|

400-600pcs frame/ 8 hours

|

|

Power supply:

|

380 volts 50 Hz 3 phase

|

|

Total weight:

|

12000kg

|

|

Line Sizes (mm)

|

23000 × 1000 × 1200

|

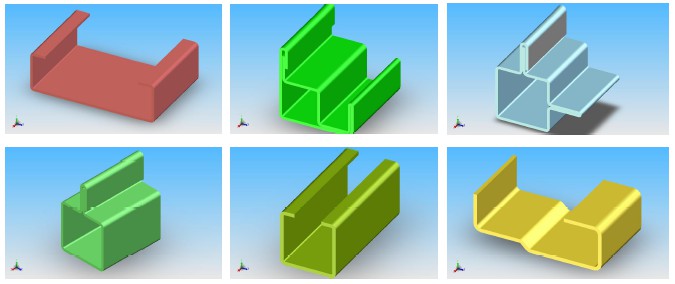

■ Electrical Cabinet Related profiles as reference

Invite inquiry for any of your custom metal track information, let us know your requirements, we will find the best solutions to meet your project.

TAG: Electrical cabinet Roll Forming Machine, Electric Cabinet, Electrical Cabinet Box Roll Forming Machine, Electrical cabinet frame profiles roll forming equipment, Roll forming machine for production Electrical Cabinet Frame, Electrical Cabinet Box Roll forming machine

Last:No

Next:Cable Tray Roll Forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,