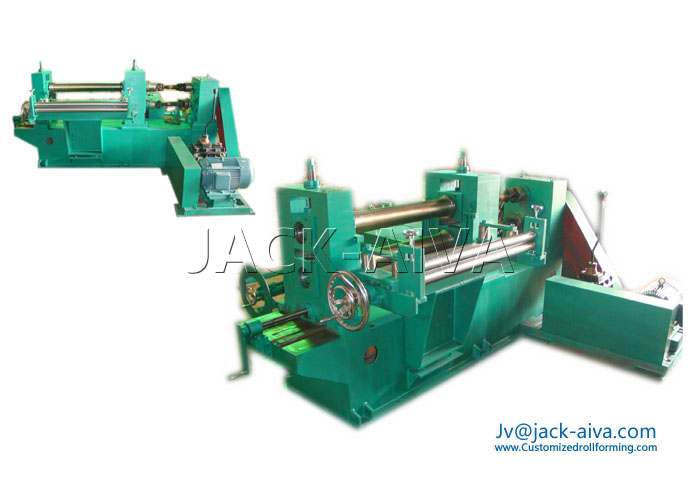

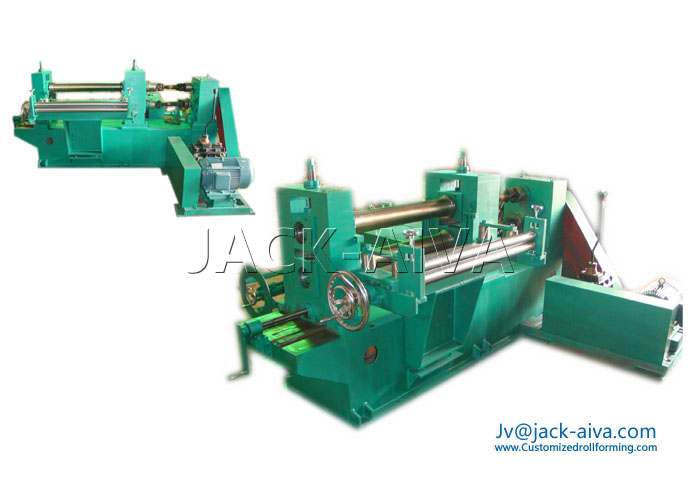

Compact Slitting Line

■ Mechanical Slitting Line General Introduction

This is the economical Slitting line machine, it is the proper solution for the client that their production quantity is not too many and the raw material width is less than 700mm. It can do uncoiling, slitting and recoiling works, make coil steel to any desired width coil steel. It mainly includes un-coiler, coil guide, slitting machine, scrap winder, tension unit, re-coiler. It mainly used in cold or hot rolled, galvanized iron, PPGI, stainless steel, carbon steel, silicon steel and all the other kinds of metal materials with surface spreading.

It’s the economical slitting line in sheet metal processing industry. Still the high precision strips can be obtained through the line. Straightening device and the other parts equipped is according to client’s requirement.

The normal equipments on the line is consisted of de-coiler, leveling part, slitting device and quality slitting blade, re-coiler, etc.

The type of machinery is suitable for accessories in small quantities production,

■ Technical information- slitting line

Material: HR, CRC, GI, PPGI, SS

Material weight: Max 2000kg

Material thickness: 0.3mm – 2.0 mm

Material width: max 800mm

Material inner diameter: 460mm~520mm

Material outside diameter: 1200mm

No.of Slitts 10~ 30 Nos

Slitting speed: 0-50m/min

Width tolerance: +/-0.15 mm

Set up Position: according client’s request.

Total power: about 11KW.

This line can be adjusted to do recoiling or dividing work to meet customer’s demand.

For continuous slitting we also can supply the Brake and Separating discs as well as the re-coiler to increase the line efficiency. The slit strips are guided through Separating discs and a felt Brake to the re-coiler. The Separating discs ensure the perfect alignment of coil edges during recoiling. A pneumatic Brake tightens the strips and can be adjusted manually.

Last:Mechanical Slitting Line

Next:Automatic Shearing & Slitting Line

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,