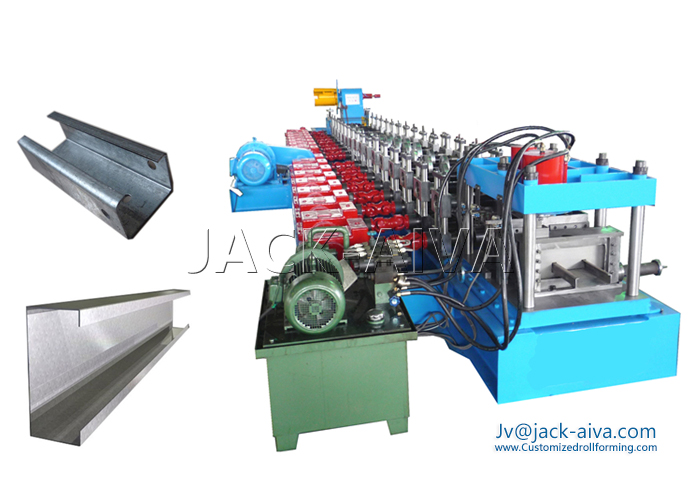

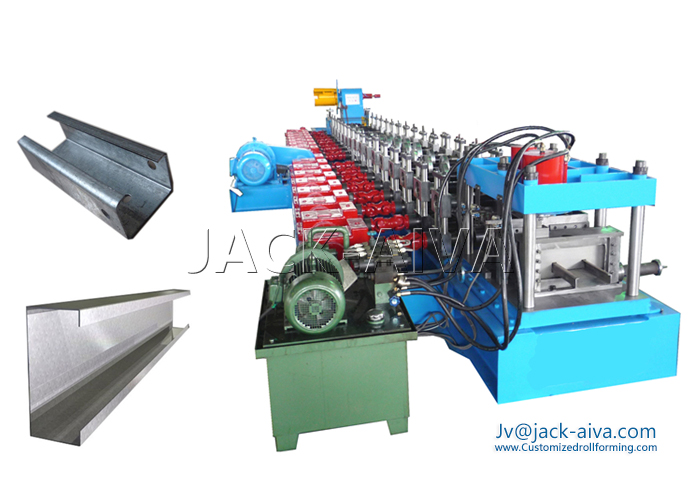

C Steel Purlin Roll Forming Machine

■ Cold Roll forming Machines for production steel Structural frame products - C Purlin

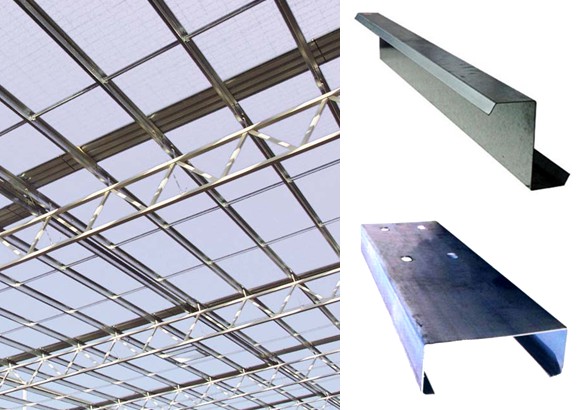

C Purlin is as an integral part of light steel structure, Purlins and Girts are roll-formed from Hi-Tensile Galvanised steel.

With the advantage of Cee purlin, it is widely adopted in Building construction Industry – commercial and residential, they are primarily used to provide lightweight, economical, efficient roofing and cladding support systems for framed structures.

■ Technology Specifications - C steel purlin Roll Forming Machine

Our Manufacturer is one of the leading suppliers in china about the C steel purlin roll forming machine, The various width C Purlin can be produced by the same line after changed the spacers and suitable size cutting moulds. This is the most popular solution for difference width C purlin by one line. And accepted by most clients.

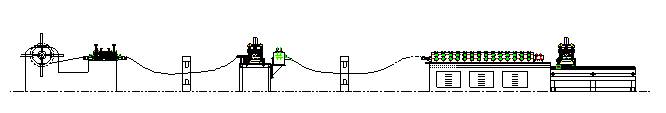

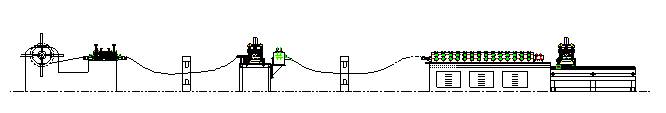

The whole roll form line is consisted of de-coiler, material feeding entrance, flatting device, holes punching equipments, main roll forming machine, hydraulic cutting part, hydraulic system, PLC control system and run out table, etc.

De-coiling---Coil sheet guiding and feeding---sheets Pre cutting------cut-to-length----Roll forming---- Hydraulic punching holes---cut to length—stacking production

■ Main Parameters- C purlin Roll forming Machine

|

Feeding material Thickness:

|

1.4-3mm (Q195, Q235)

|

|

Forming station:

|

20 sets

|

|

Material of roller:

|

Quality moulds steel, polished and coated with chrome, hardness HRC58-62

|

|

Forming Roller Stations:

|

20 Stations, quality casting steel after precision processed.

|

|

Main power:

|

15KW

|

|

Hydraulic station power:

|

5.5KW

|

|

Hydraulic pressure:

|

10-12Mpa

|

|

Leveller

|

4KW

|

|

Control system:

|

PLC Control with touch Screen, Inverter, Encoder are MITSUBISH or Panasonic Brand Japan

|

|

C PURLIN:

|

Width:100-300mm;

|

|

High: 40-85mm

|

|

Z Purlin:

|

Width: 100-300mm

|

|

HIGH:40-85mm

|

|

Product length tolerance

|

2M+/- 1.0mm

|

|

Line speed:

|

10-15m/min (not including cutting material time)

|

|

Size of main machine:

|

11000×1800×1800mm

|

|

Equipment weight:

|

7500kg

|

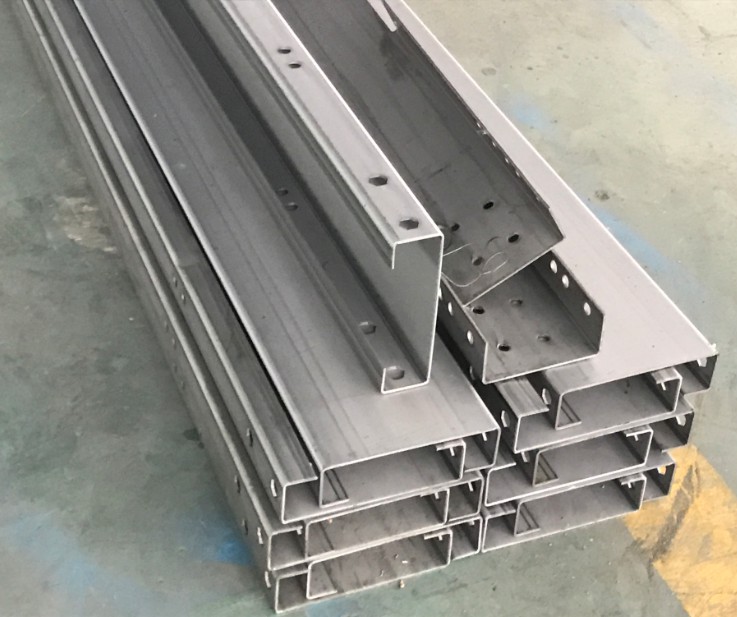

■ C Steel Purlin Section

- The manual decoiler or hydraulic decoiler can be optional.

- The normal driving system is controlled by chains. Gearing box with cardan shaft also can designed according to your request.

- Standard C purlin profile drawing as following,

- We can send the best solution and design different style C & Z Purlin roll forming machine according to client’s requirements, such as holes punched after profile roll formed, or pre- punched, etc. We can do a custom roll forming machine, i.e. we can design the machine according to your specification and profile drawing. Complex questions will be simple here.

■ Application - C PURLIN SECTIONS:

C sections have flanges which are equal in size and are commonly used for simple supported spans. C sections cannot be lapped continuous spans in multi-bay buildings, but easily adapted for use in small and medium sized buildings as structural framework.

TAG: C Purlin Roll Forming Machine, C Steel Purlin Machine

Last:No

Next:C Steel Purline Roll Forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,