Double layer Roofing Machine

■ Roll Forming Machine for production Corrugated Roof panels & Trapezoidal Roof Panel

The automatic double layer roofing machine can produce two different steel roofing sheets, and without changing any rollers or cutting die, just Switching clutch will be the whole operation. As there are two sets of rollers and cutting device installed on this double layer roll forming machine. If client do not want to spend too much working site to machines, and the quantity request is not too many, Then this automatic double layer roof panel machine is the good solution.

From this roll forming machine, the corrugated sheets and trapezoidal roof panel can be produced by top set and bottom set of forming roller. The roof panel profile is according client request. The roof panel surface by this double layer roof panel machine is beautiful and without any scratch. this is same as singer layer roofing machine.

Our manufacturer is one of the leading supplier and manufacturer in china and have been supplying and making roll forming equipment for the metal building construction industry for a long time We have full ability to supply almost all the panel making machines.

Our automatic double layer roofing roll forming machines are manufactured with advanced technology from abroad. The whole line consists of un-coiler and its base, coil sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, controlling system, and run out table

■ Main Parameters - Automatic double layer roofing machine

|

Main motor power::

|

5.5kw

|

|

hydraulic station power:

|

2.2kw

|

|

Hydraulic pressure:

|

10-12Mpa

|

|

Forming Speed:

|

70000-12000 mm/min

|

|

Control System :

|

Fully Automatic Control System with PLC, Easy operation: Key in the length and quantity on the control panel

|

|

Capacity Length:

|

up to 9999 mm (optional)

|

|

Material of Sheet:

|

Soft Quality (Annealed) Galvanized Sheet

|

|

Sheet Thickness:

|

0.4 to 0.6 mm

|

|

Total Gross Weight:

|

About 6000kgs

|

|

Line size (Lx w x h)

|

11000 mm×1500 mm×1100 mm

|

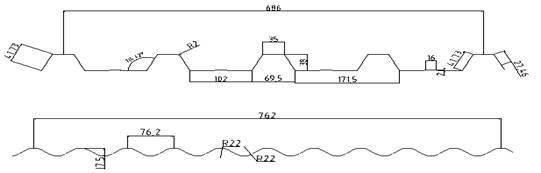

■ Roof panel profiles

One roll forming machine only can produce one profile. The following profile drawing are some examples for your reference.

We can manufacture as per customer provided drawings with specification or real objects of sectional materials, custom roll forming machine is welcome.

More information about roof panel profiles, Pls contact with us!

TAGS: Double layer Roofing Machines, Roll Forming Machine, Double decking roof panel machine

Last:Steel Decking Machine

Next:Duplex Cladding Sheet Forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,