Drywall Stud Roll forming Machine

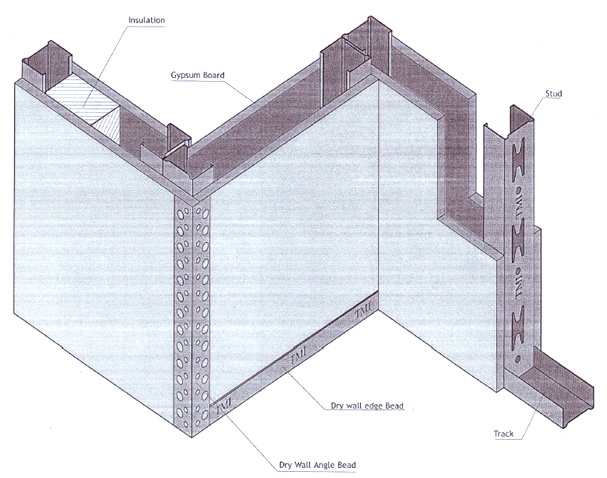

■ Drywall Partitioning Beam System- Stud

The drywall partitioning system is widely adopted in offices and residential buildings, because of its easiness of installation and the possibility of making changes any time after installation without infrastructure.

In addition It's considered as economic and liable solution for dividing any open area with considering the fact that it is not designed for applying high loads.

The drywall partition beam system are consisted of stud, track, drywall angle bead and drywall edge bead, etc.

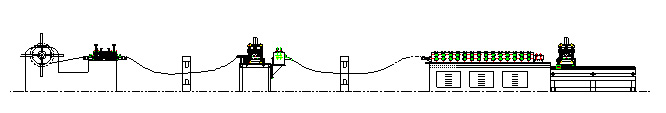

■ Brief Introduction- Stud Roll Forming Line with holes punching online

Our Drywall partition beam roll forming machine comes in semi auto and fully auto models which can produce many types of thin gauge cold formed steel. The Drywall stud Roll Forming Machine is consisted of de-coiler, hydraulic punching device, main roll forming machine, servo control hydraulic tracing cutter and run out table (flexible style discharge table). The line speed is designed according to 20m/min. The driving system is by reducer and main gearing box.

■ Roll Forming Line technology flow

Manual De-coiling (3 tons)+leveler (2 in 1)--- Servo motor control Feeder + Hydraulic punching with hole punching moulds--- Main Roll forming Machine ---- run out table (flexible style discharge table IS Optional)

■ Main Parameters- Drywall Studs Roll Forming Machine

|

Line structure

|

Portal-type frame style, A3 steel

|

|

Raw material thickness

|

0.5-0.6mm

|

|

Raw material width

|

According to profile sizes

|

|

Forming Roller Stations:

|

16 Stations

|

|

Forming Roller shaft:

|

Φ42mm

|

|

Forming rollers

|

SKII, Quenching, hardness HRC62-64º

|

|

Forming Speed:

|

12 meters / min

|

|

Main motor:

|

7.5kw

|

|

Material of Sheet:

|

Soft Quality (Annealed) Galvanized Sheet

|

|

Cutting mode:

|

Hydraulic tracing cutter, driving by servo motor

|

|

Line speed

|

20m/min (adjustable)

|

|

Control Cabinet

|

3xAC380v, 50HZ

|

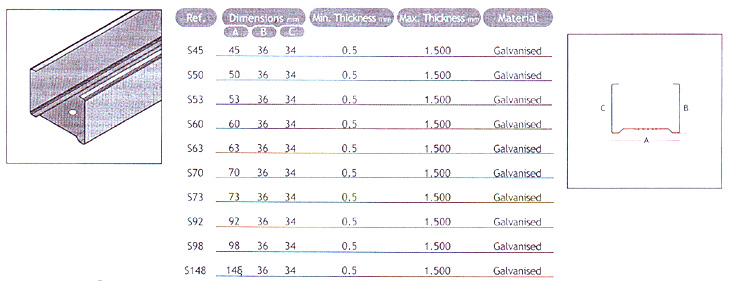

■ Drywall Partition Sections- Stud

We introduce the most cost effective Steel stud manufacturing cold roll forming technology for producing light gauge steel sections for commercial building frames ( stud wall construction ) and also roof trusses. There are many kinds of profiles of the dry wall partition beam & stud partition as the different market has the different requirement, we design and produce the forming machine according to clients’ drawings or samples normally.

The following are the typical drywall stud sizes list for your reference.

■ Roll forming machine for manufacturing the production profiles for Ceiling & dry Wall system

TAG: Drywall Stud Roll forming Line, Drywall Partition Beam

Last:No

Next:Drywall Track Roll forming Machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,