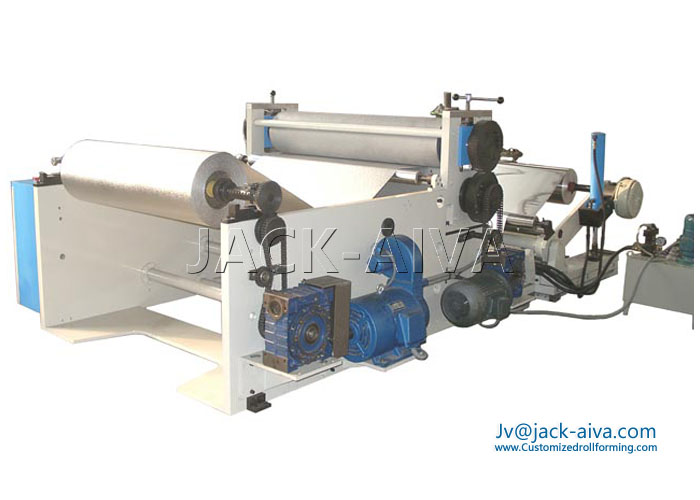

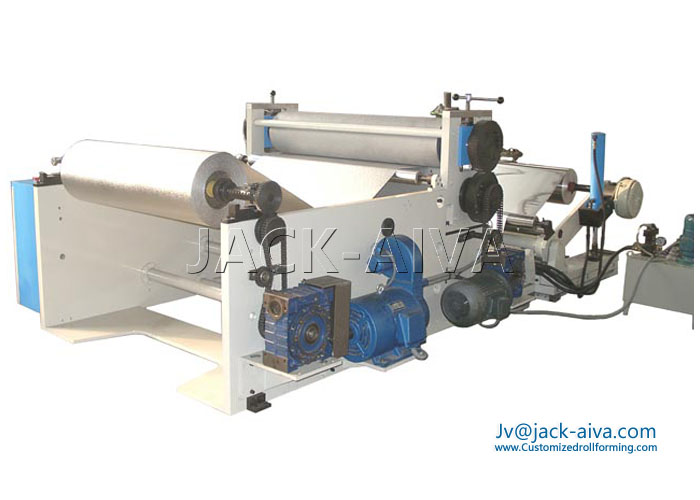

Aluminum foil embossing machine

■ Aluminum Foil Embossing rolling line Brief Introduction

The whole aluminum foil embossing line is consisted of De-coiler, re-coiler, solid roller material embossing rollers and hollow embossing rollers and electrical control system.

We provide customers worldwide with quality engraved rolls and plates, and can offer customers expanded choice and increased manufacturing flexibility. With full-range of embossing machinery, applications include construction, filtration, agricultural and medical industry.

Our metal sheet embossing machinery are constructed on proven technologies and custom-built to exact parameters essential to your application and product.

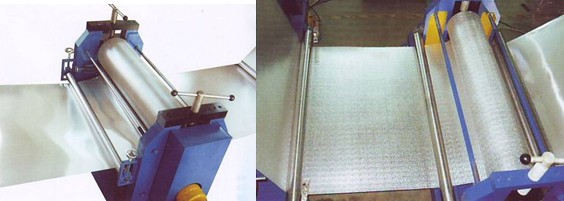

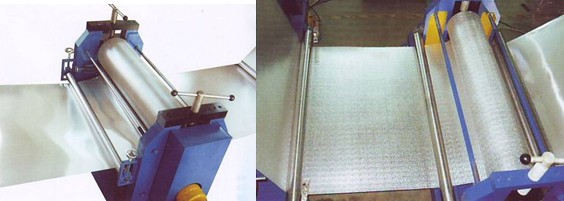

Embossing is a metal forming manufacturing process by means of male and female harden metal rollers (dies) to form raise or sunken patterns on sheet of metal. In cases where the patterns on both sides of the panels have to be matched, a set of well-matched engraved counter rollers will be necessary. This will ensure the panels are aesthetic from the inside as well as outside.

■ Aluminum foil embossing machine characters

l It is mainly applied in embossing of non ferrous metal thin boards, such as aluminum board, color steel board, stainless steel board, garage door, refrigerator, cold house, constructive and decorative materials, etc.

- The pattern is processed by concave and convex counter pressing, and its depth can be adjusted through the screw.

- Material of roller: alloy steel, 42CrMo, 40Cr, 60CrMnMo, 9Cr2M.

- The solid of forged piece of roller is quenched, tempered and processed by heat treatment HRC55-62.

- The gear drive between rollers is precise and of no clearance.

- It can be applied to thin roll and sheet.

-The winder and un-winder are of cylinder moving top disc type or expansion cylinder type.

Last:Metal Sheet Embossing Machine

Next:Colored steel embossing machine

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,