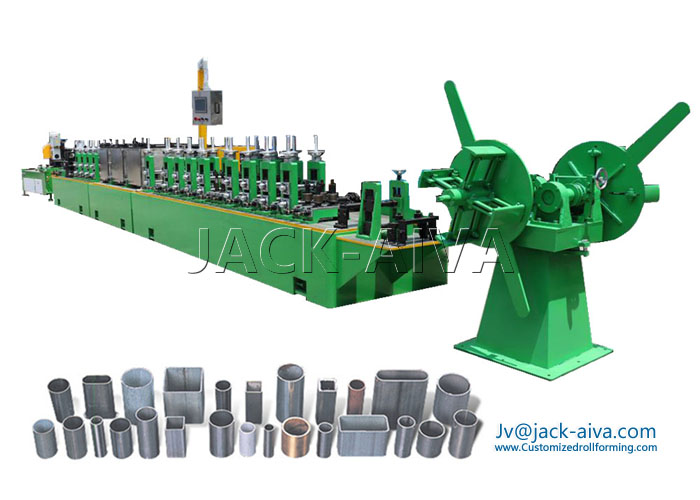

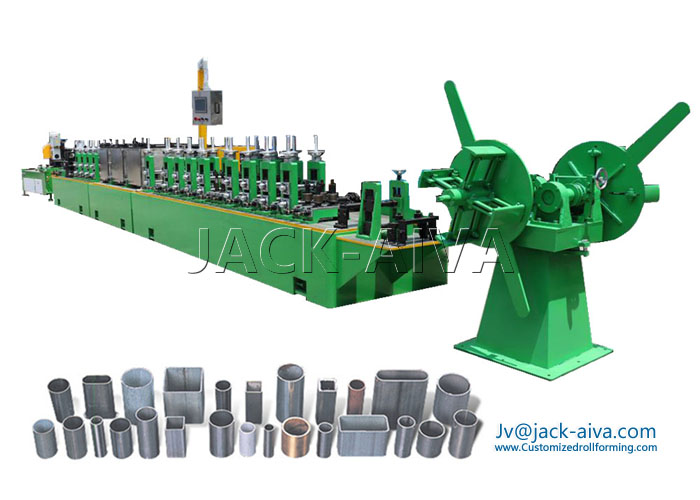

Tube welding Machine

■ Tube forming & TIG welding line Technology specifications

TIG Pipe welding technology and high-frequency Pipe Welding technology are the two important solutions for production metal pipe in the present market. With our engineers so many years experience in this roll forming industry, we have full ability to supply the right solution according to the client requirements or production sample.

If clients never mind the line speed, the argo arc welding style pipe forming and welding machine is the best choice for the thin wall welding profiles, because of its high welding quality and low cost, it is very popular in the market. The speed is 8-15m/min.

■ Manufacture of TIG-welded tubes

Tungsten-inert gas welding presents itself, in spite of competitive Laser welding, as an interesting alternative for the manufacture of high quality tubes. This technology is comparatively easy to master and the investment costs are low.

As with all other welding processes, the rollforming machine transforms the flat sheet metal into a tube. During the welding phase, an electric arc burns inside a protective gas covering (Argon-Helium mixture or pure Helium) between a non melting tungsten cathode and the strip edges. Multi-cathode welding torches are used when it is necessary to increase the welding speed or when producing tubes of large dimensions. Direct or alternating current is used according to the application in question.

DREISTERN supplies outstandingly successful TIG-welding installation for thin-walled stainless steel tubes or for aluminum-plastic composite tubes.

Last:Oval Duct Production Line

Next:No

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,