Cut- to-length Line

■ Products Information

■ General Introduction - Cut To Length Line

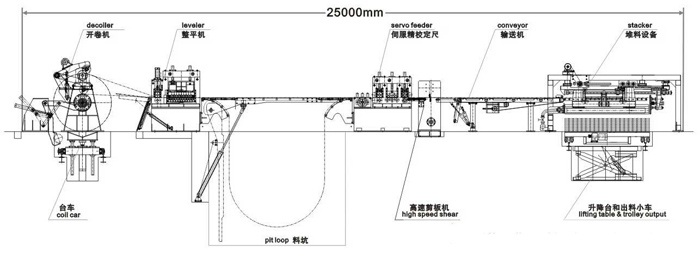

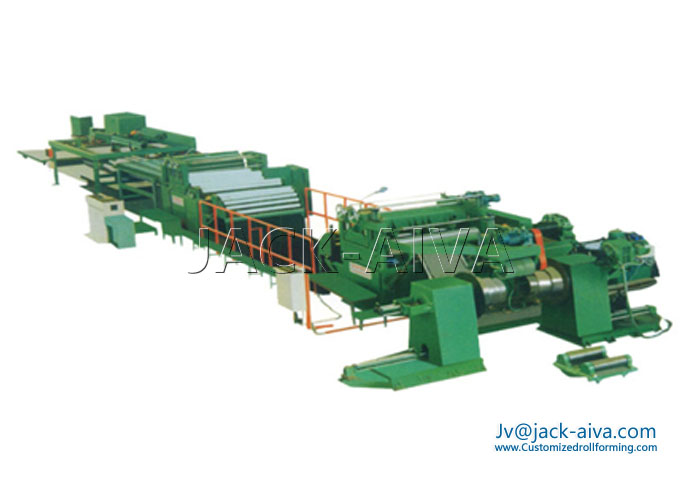

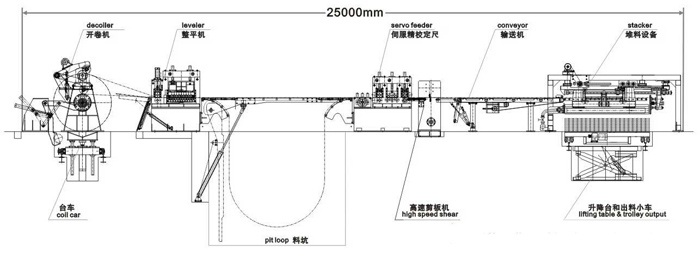

High speed uncoiling-leveling-cut to length-stacking line

Our Metal sheet high speed Cut to Length Lines can do uncoiling, leveling, measuring, cross-cutting to length and stacking work. It mainly includes un-coiler, leveler, measuring encoder, shearer, conveyor, stacker, hydraulic system, pneumatic system and electrical system, etc., the line can make sure of accurate feeding and shearing. It can be widely used in cold or hot rolling carbon steel, tinplate, stainless steel and all the other kinds of metal materials with surface coating.

The metal sheet cut to length line is controlled by PLC system. It has PLC controlled the length measurement. The information of length, shearing numbers and speed can be input to the PLC systems. When the need shearing number is reached the line can stop automatically. The line speed can be adjusted, It has a encoder with high precision, and whole line can work automatically and operate easily, smooth sheet can be made.

■ LIST OF EQUIPMENTS UNDER SCOPE OF SUPPLY

1. Coil car

2. Double Cone Decoiler

3. Snubber Arm.

4. entry support peeler table

5. straighener

6. roller table

7. Side Guide Roller

8. The leveler

9. end plate run out pinch roll

10. Hydraulic Shearing Machine

11. stacking table

12. Hydraulic Systems

13. Pneumatic Systems

14. Electrical System PLC Control

■ Main Technical Parameters

|

Metal steel cut to length line |

|

Model |

Sheet Thickness

(mm) |

Coil Width

(mm) |

Leveling Accuracy |

Tolerance |

Line Speed

(m/min) |

Coil Weight

(Ton) |

|

(mm/㎡) |

(mm/m) |

|

2*1300 |

0.3-2 |

400-1300 |

1.5 |

±0.5 |

40 / 60 |

10 / 15 |

|

2*1600 |

0.3-2 |

400-1600 |

1.5 |

±0.5 |

40 / 60 |

15 / 20 |

|

3*1050 |

0.4-3 |

300-1050 |

1.5 |

±0.5 |

40 / 60 |

10 / 15 |

|

3*1300 |

0.4-3 |

400-1300 |

1.5 |

±0.5 |

40 / 60 |

10 / 15 |

|

3*1600 |

0.4-3 |

400-1600 |

1.5 |

±0.5 |

40 / 60 |

15 / 20 |

|

4*1300 |

0.5-4 |

400-1300 |

1.5 |

±0.5 |

40 / 60 |

10 / 15 |

|

4*1600 |

0.5-4 |

400-1600 |

1.5 |

±0.5 |

40 / 60 |

10 / 15 |

|

4*2000 |

0.5-4 |

500-2000 |

1.5 |

±0.5 |

40 / 60 |

15 / 20 |

|

6*1600 |

1-6 |

400-1600 |

1.5 |

±0.5 |

40 / 60 |

20 / 25 |

|

6*2000 |

1-6 |

500-2000 |

1.5 |

±0.5 |

40 |

20、25 |

Last:Slitting Line

Next:Mechanical Slitting Line

+86-512-58162555

+86-512-58162555

86-512-58162555(Tel)

86-512-58162555(Tel)  XINTANG ROAD ECONOMIC DEVELOPMENT AREA,

XINTANG ROAD ECONOMIC DEVELOPMENT AREA,